News

Basic Types of Electroplated Huai'an Hangers

Jun 12,2023

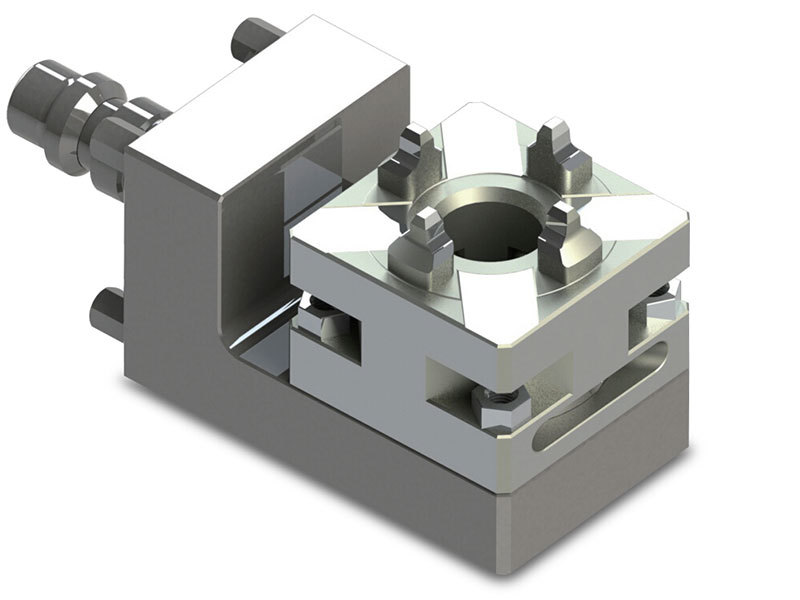

Electroplating fixtures come in different types based on the shape of the parts, electroplating technical requirements, electroplating process, and equipment size. For example, there is a difference between automatic and manual lines. Generally, electroplating workshops are equipped with universal hangers for various common parts, and only specialized hangers designed and manufactured for certain parts. There are many types and forms of general hanging tools that are suitable for various processes and parts.

Hangers can be divided into two situations: one is a specialized hanging tool designed and manufactured specifically for mass production of parts; Another type is a special hanger designed based on the complex geometric shape of the parts and special process requirements.

Using hanging tools:

Hangers are suitable for various parts and processes. The form and structure of a universal electroplating hanger should be determined based on the geometric shape of the plated parts, technical requirements for the coating, process methods, and equipment dimensions. For example, sheet electroplated parts will drift downwards between the next steps due to the resistance of the plating solution. When selecting hanging tools, the plated parts should be clamped or tied tightly with copper wire. If the plated part is heavy and has holes, a hook shaped hanger can be used. The usage requirements are as follows:

1) Hangers are used for manual operation. The loading capacity is generally 1-3 kg.

2) The hook should have sufficient conductive area and its type should make it conductive. Hanger hooks should be cleaned regularly.

3) When using, care should be taken to handle it gently and avoid damaging the insulation layer as much as possible. Otherwise, the hanging tool will compete with the workpiece for power, causing the workpiece to be unable to be locally electroplated or rough, affecting the coating quality.

4) Hangers should be cleaned and properly stored for future use after use.

5) If the hanging device is used for a period of time, it should be treated in a timely manner and the coating on the hanging device should be removed to ensure good conductivity. Cracks in the insulation layer of the hanging appliance should be repaired or re insulated in a timely manner.

News