News

Application and Introduction of Clamping Fixtures

Jun 12,2023

Tooling, also known as process equipment, refers to the general term for various tools used in the manufacturing process. Including cutting tools/fixtures/molds/measuring tools/inspection tools/auxiliary tools/bench tools/workstation tools, etc. Tooling is its general abbreviation.

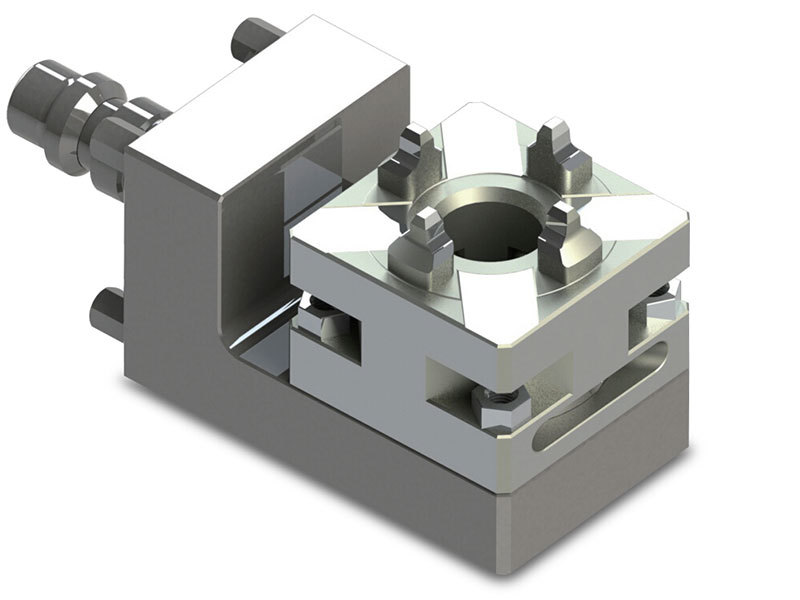

A fixture is a process device used to quickly tighten the workpiece during processing, ensuring that the machine tool, cutting tool, and workpiece maintain the correct relative position. That is to say, Workholding fixtures are indispensable components for mechanical processing. Driven by the development of machine tool technology towards high-speed, efficient, precise, composite, intelligent, and environmentally friendly directions, fixture technology is developing towards high-precision, high-efficiency, modular, modular, versatile, and economical directions.

Fixture, also known as fixture. In a broad sense, any device used to quickly, conveniently, and safely install workpieces in any process can be referred to as a fixture. For example, welding fixtures, inspection fixtures, assembly fixtures, machine tool fixtures, etc. Machine tool fixtures are the most common and often referred to as fixtures.

When processing workpieces on a machine tool, in order to ensure that the surface of the workpiece can meet the technical requirements of the dimensions, geometric shapes, and positional accuracy with other surfaces specified in the drawing, the workpiece must be installed (positioned) and clamped (clamped) before processing.

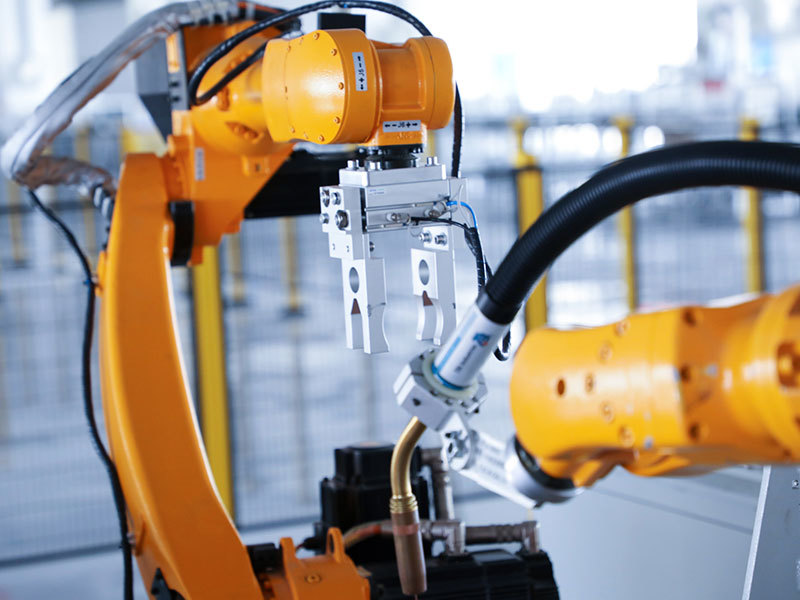

The application of machine tool fixtures is conducive to ensuring the machining accuracy of the workpiece and stabilizing product quality; Beneficial to improving labor productivity and reducing costs; It is conducive to improving the working conditions of workers and ensuring safe production; It is conducive to expanding the scope of machine tool technology and achieving "one machine with multiple uses".

Fixtures are usually composed of positioning components (to determine the correct position of the workpiece in the fixture), clamping devices, tool guide components (to determine the relative position of the tool and the workpiece or guide the tool direction), indexing devices (to enable the workpiece to complete processing of multiple workstations in one installation, there are two types of indexing devices: rotary indexing devices and linear moving indexing devices), connecting components, and clamp specific (fixture base).

Fixtures are also highly used by electronic manufacturers. In order to improve production efficiency and product quality, fixture fixtures are commonly used in the middle and later stages of production for functional testing or auxiliary assembly (which can assemble fixed shapes and heights, etc.). The actual use in electronic production factories is very wide, because it is non-standard customization, so there is nothing that cannot be achieved but unexpected.

News